Aluminium Hydride Reagents

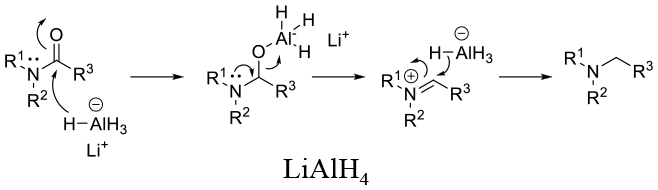

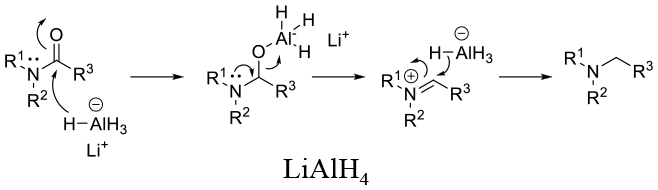

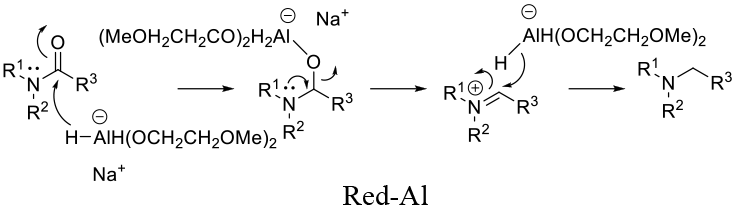

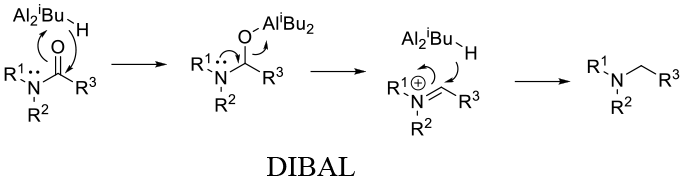

Mechanism + Description

Mechanism involves hydride addition followed by C-O bond cleavage –possibly via an iminium species (or concerted collapse by intramolecular Hydride delivery). A driving force is the Formation of the Al-O bond.

General comments

The three most common Al hydride employed for amide reduction are lithium aluminium hydride (LAH), Sodium bis(2-methoxyethoxy) aluminum hydride (Vitride, Red –Al) and diisobutyl aluminium hydride (DIBAL). Reactivity is LAH > Red –Al > DIBAL. All are powerful reducing agents and compatibility with other reducible functional groups can be problematic. Occasionally some selectivity can be obtained by the correct choice of reagent, solvent and temperature. All reagents generate Al salts on hydrolysis and hydrogen. DIBAL will also generate isobutane.

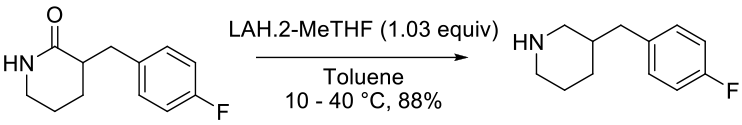

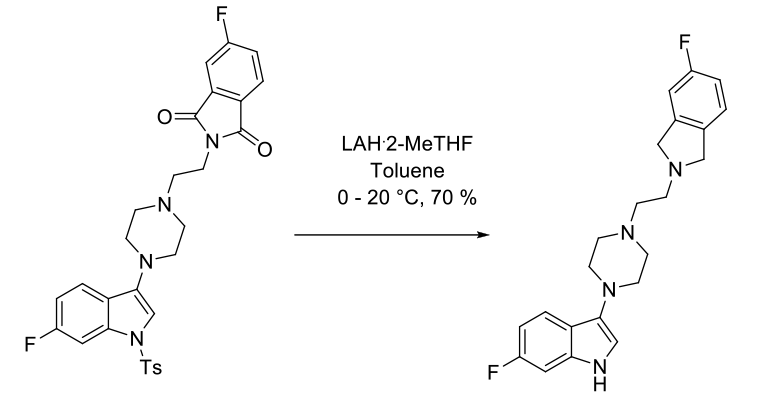

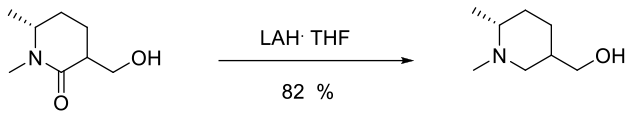

LAH – Works on 2° and 3° lactams as well as 1° amides. Its used as solid LiAlH4 or a solution of LiAlH4. THF complex in toluene. Solvent: THF /ethers or toluene

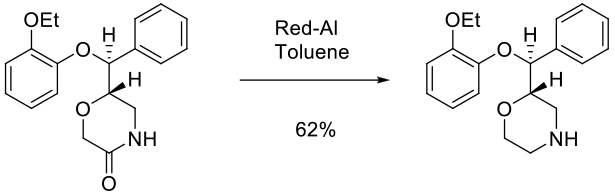

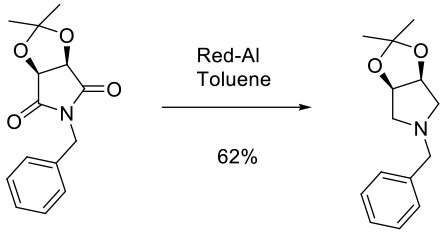

Red-Al – Works on 2o (lactam) and 3o amides Solvent: toluene, ethers (10 °C to reflux)

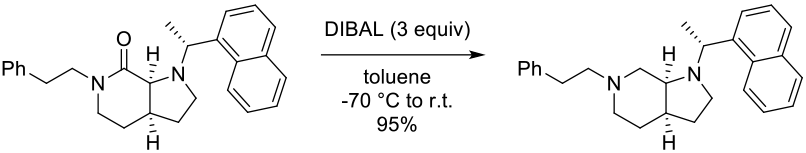

DIBAL – Works on 3° lactams , Solvent: toluene (aliphatic or aromatic hydrocarbons)

Key references

J. Org. Chem., 1953, 18, 1190–1200 The Reduction of Acid Amides with Lithium Aluminum Hydride

e-EROS Encyclopedia of Reagents for Organic Synthesis Sodium Bis(2-methoxyethoxy)aluminum HydrideOrg. Synth. 2006, 83, 141 reduction of pyridinone to piperidine with LiAlH4

Org. Synth. 2006, 83, 70 reduction of aliphatic t-amide with LiAlH4

Relevant scale up example

Experimental

7 kg scale

Org. Process Res. Dev. 2006, 10, 262-271

Experimental

6 kg scale

Org. Process Res. Dev. 2003, 7, 521-532

Experimental

2 kg scale

Org. Process Res. Dev. 2013, 17, 61−68

Experimental

100 kg scale

Org. Process Res. Dev. 2007, 11, 346-353.

Experimental

150 kg scale

Contains DOE study

Org. Process Res. Dev. 2004, 8, 834-837

Experimental

40 g scale

Org. Process Res. Dev. 2007, 11, 711-715

Green Review

-

Atom efficiency (by-products Mwt)

- LiAlH4

By-products: 2 eq LiOH (24 g/mol) + 2 eq Al(OH)3 (78 g/mol) + 2 eq H2 gas (2 g/mol) = 208 g by-products/mol amide. Large quench volumes generate further waste - DIBAL-H

By-products: 2 eq Al(iBu)2OH (158 g/mol) = 316 g by-products/mol amide - Red-Al

By-products: 2 eq of NaOH (40 g/mol), 2 eq AlH(OEtOMe)2OH (195 g/mol) = 470 g by-product/mol amide

- LiAlH4

- Safety Concerns

Major concerns are around the pyrophoric nature of most Aluminium hydride reagents, and generation of hydrogen during reaction and quench. Red-Al is the least pyrophoric of this class of reagent. - Toxicity and environmental/aquatic impact

Aluminum hydrides can cause severe burns. In the environment rapid hydrolysis to insoluble Aluminum oxide /hydroxides will occur (pH range 5 to 8). Typically regarded as non-toxic, concern over possible Al toxicity is rising. - Cost, availability & sustainable feedstocks

Most Aluminum hydride reagents are available in bulk at reasonable cost. They are not available from renewable sources. - Sustainable implications

None with Aluminum. Lithium is at moderate risk of depletion. LiAlH4 reactions are being reported in greener ether solvents like CPME and 2-methylTHF