Achiral Metal-catalysed Reduction

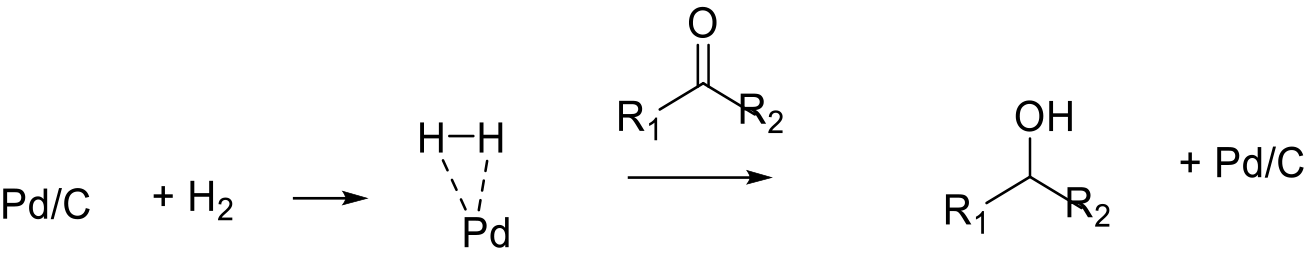

Mechanism + Description

Activation of hydrogen on a metal particle followed by coordination of the ketone and transfer of hydrogen to give the alcohol product.

General comments

Both homogeneous and heterogeneous metal catalysts can be employed for the catalytic reduction of ketones, although in practice most scaled hydrogenations use heterogeneous catalysts for the ease of separation from the product stream, and reuse or recycling of the metal component. Most traditional metal-based hydrogenation catalysts like Pd, Pt, and Ru on inert supports such as carbon, alumina, silica, etc., can be used for ketone reduction. Base metal catalysts such as Raney Ni, etc., can also be employed. Typical H2 pressures of 1 to 5 bar are used. Selective reduction in the presence of other educible functional groups can be achieved by correct choice of catalyst/support and the presence of various additives.

In the absence of an H2 source, transfer hydrogenation can be used to reduce ketones using heterogeneous precious and base metal catalysts—the hydrogen coming from a sacrificial donor which is decomposed to generate free H2 gas, or nascent H2 on the catalyst surface.

Key references

Wang, D.; Astruc, D. The Golden Age of Transfer Hydrogenation. Chem. Rev. 2015, 115, 6621-6686.

Relevant scale up examples

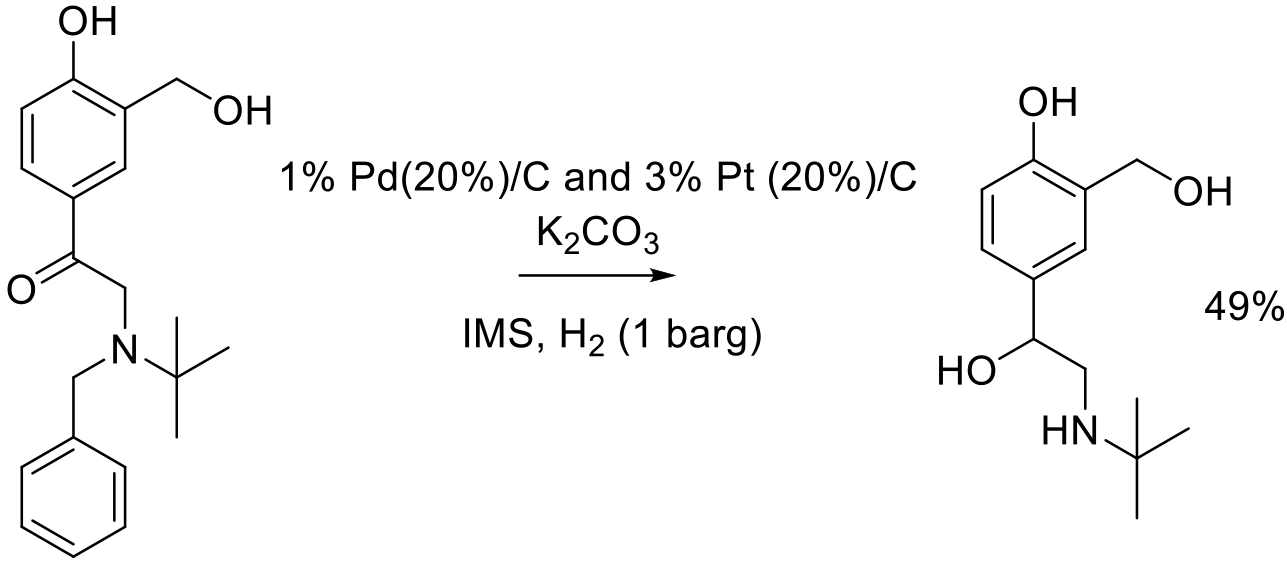

Org. Proc. Res. Dev. 2017, 21, 1806-1814.

20 g scale

Green Review

-

Atom efficiency (by-products, molecular weight)

With optimized catalytic efficiency, heterogenous metal-catalyzed hydrogenation is an atom efficient process generating water /low molecular weight byproducts. Transfer hydrogenation can vary from good to poor depending on the molecular weight of the donor, and the excess above stoichiometric that has to be employed. The byproducts are water and the oxidized donor and related byproducts (isopropanol/acetone, hydrazine/N2. cyclohexene/ benzene, formate / CO2, etc. Occasionally large excesses of donors are used due to unproductive production and loss of H2 or to increase reaction rate. - Safety Concerns

Typified by normal hazards around hydrogenation reactions. Catalytic transfer hydrogenation may avoid the need to handle H2 gas, but these reactions may generate H2 in situ. Reduction maybe exothermic. Dry metal hydrogenation catalysts can be pyrophoric and are usually handled water-wet—mixtures of solvent and catalyst in the presence of air can ignite. Appropriate care needs to be taken after processing in handling the spent catalyst, and this can be recycled. Some Pt salts used as catalyst precursors are strong sensitizers. Some Ni2+ salts are carcinogenic and becoming regulated under legislations like REACH. Transfer hydrogenation reactions can produce H2 gas and thus produce a flammable atmosphere above the reaction. Safety attributes of the individual donors/ byproducts need consideration. Hydrazine and benzene are suspected carcinogens. Borohydride will generate hydrogen gas on quenching and produce boric acid. Boric acid is suspected to be reprotoxic. - Toxicity and environmental/aquatic impact

The main concern is around solubilization and loss of precious metal/ heavy metal catalysts into waste streams. Most PMC/base metal levels are tightly regulated. The same applies to potential carry through into the API. Relevant guidance for metal levels from ICH/FDA/EMEA should be consulted. Some Ni salts are sensitizers and carcinogens and listed on the EU SVAH list (echa.europa.eu/candidate-list-table). This is of less concern for metallic hydrogenation catalysts. Transfer hydrogenation is generally good, although ammonia and phosphate may cause issues with discharge into water. Higher molecular weight. Terpenes and siloxanes may bioaccumulate. Boron compounds maybe more ecotoxic in the aqueous environment than previously thought. - Cost, availability & sustainable feedstocks

H2 is cheap and non-polluting and can be produced from renewable resources and electrolysis of water (may not yet compete with H2 from methane).Transfer hydrogenation – most H2 donor molecules are readily available and cheap. - Sustainable implications

All metals have a high LCA impact from mining and refining operations, so use should be catalytic with efficient recovery and recycle. Pd is most commonly used precious metal for hydrogenolysis and this is rated at high risk of depletion. Platinum group elements (Pt, Ru, Pd, Os, and Ir) are flagged as having a very high relative supply risk index value (2011 British geological Survey Risk list); No concern for abundant base metals like Ni, Co, or Fe.

Transfer hydrogenation – some H2 donors can be obtained from sustainable or biorenewable sources, e.g., isopropanol, formate, terpenes.