Biocatalysis Biocatalytic Methods for Oxidation

Mechanism + Description

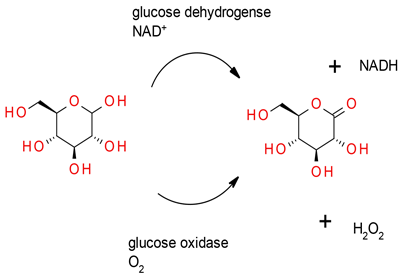

Most enzymatic alcohol oxidations occur via two principal pathways – alcohol dehydrogenase or alcohol oxidase. Oxidase enzymes contain metals at the active site – usually copper – that are active in the mechanism of oxidation, removing hydrogen to generate the carboxyl function. The metal is re-oxidised with O2 giving H2O2 as a by-product. This may have to be removed by the addition of catalase since high concentrations of H2O2 can deactivate enzymes. ADH enzymes work by removing H+ followed by H- generating a carbonyl group and effectively transferring the H2 to an oxidised co-factor NAD+ or NADP+. To drive the catalytic cycle, the reduced co-factor needs to be reoxidized either enzymatically or chemically.

Most enzymatic alcohol oxidations occur via two principal pathways – alcohol dehydrogenase or alcohol oxidase. Oxidase enzymes contain metals at the active site – usually copper – that are active in the mechanism of oxidation, removing hydrogen to generate the carboxyl function. The metal is re-oxidised with O2 giving H2O2 as a by-product. This may have to be removed by the addition of catalase since high concentrations of H2O2 can deactivate enzymes. ADH enzymes work by removing H+ followed by H- generating a carbonyl group and effectively transferring the H2 to an oxidised co-factor NAD+ or NADP+. To drive the catalytic cycle, the reduced co-factor needs to be reoxidized either enzymatically or chemically.

General comments

Biocatalytic oxidation is generally very safe, occurring in water or water – solvent mixtures at near ambient. Reagents are formed from natural sources and readily degrade. Issues with exotherms and delayed exotherms often encountered with chemical oxidations are absent, although if air needs to be supplied as a terminal oxidant care needs to be taken with generating flammable mixtures if organic solvents are present. When handling proteins, appropriate care needs to be taken to prevent operator exposure since they can cause sensitisation.

Key references

ChemCatChem 2012, 4(6), 739-749 – A review of biocatalytic oxidation of primary and secondary alcohols

Green Chem., 2011, 13, 226-265 – An overview of enzyme-mediated oxidations for the chemist

Practical Methods for Biocatalysis and Biotransformations 2 (2012) – Common and useful preparation procedures including subtle chemo- and stereo-selectivity examples

Relevant scale up example

Green Review

-

Atom efficiency (by-products Mwt)

Atom efficiency depends on the terminal oxidant and any co-factor recycling required. Oxidases using O2 give H2O as the by-product. Dehydrogenases need co-factor recycle. If using whole cells, this may be possible through cell metabolism. If not, other enzyme and / or chemical oxidants can be employed ideally the choice should be made so as to minimize any mass burden on the process. - Safety Concerns

Generally biocatalytic methods are free of thermal events and can be managed in standard equipment. - Toxicity and environmental/aquatic impact

The biocatalysts are commonly biodegradable and pose minimal environmental hazards. Some of the proteins, especially dusty solids can be sensitizing (R42) so appropriate handling should be employed. For use in c-GMP manufacture of API, enzymes from mammalian sources or those fermented using mammalian products should be avoided. Older work using whole cells and biphasic systems often use dialkyl phthalates as the organic phase. These materials are persistent, can be endocrine disruptors and restricted under REACH – hence should be avoided. - Cost, availability & sustainable feedstocks

Many enzymes are now becoming commercially available in bulk, and many CRO’s can offer biocatalysis and enzyme development services. In most cases, at the pilot stage, a biocatalysed reaction will cost more than an chemical alternative (fermentation / enzyme supply is very sensitive to economies of scale), but at full scale most biocatalysed processes are greener and cheaper than chemical alternatives. - Sustainable implications

Enzymes are produced from renewable materials and are fully biodegradable back to innocuous natural products (amino acids). The use of modern molecular biology and fermentation technology has greatly reduced the LCA of enzyme manufacture. Maximum sustainability benefits are usually obtained with mutant recombinant enzymes rather than natural enzymes.