Alcohol Oxidase

Mechanism + Description

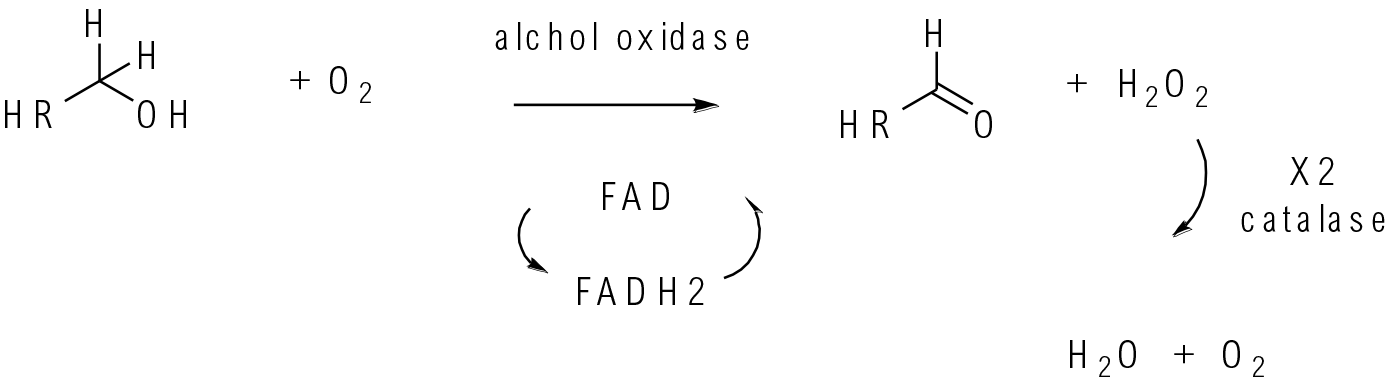

Alcohol oxidases contain either a Cu or flavin adenine dinucleotide (FAD) cofactor and oxidise alcohols to aldehydes in a two-electron process thus producing H2O2 as a by-product.

General comments

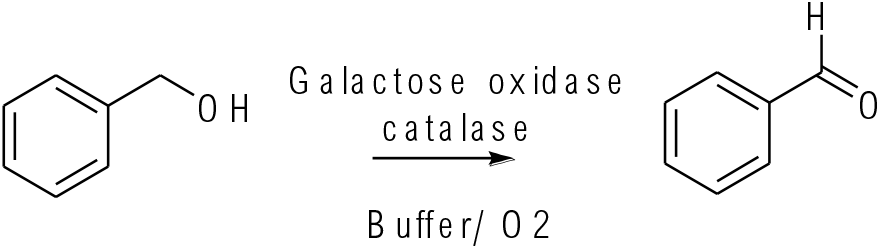

Alcohols can be oxidised by ADH/KRED enzymes if the NAD/NADP cofactor recycle is pushed in the right direction. Alcohol oxidases use a different mechanism and use a metal or flavin cofactor O2 as the terminal oxidant generating peroxide. Since this by-product is highly deactivating to most enzymes, catalase is often added to cause dismutation to O2 and H2O. Thus, alcohol oxidase represents a selective green oxidation of primary alcohols to aldehydes avoiding stoichiometric heavy metals or hypervalent iodine reagents, etc. Alcohol oxidase have also been evolved that will oxidise secondary alcohols to ketones with O2.

Key references

Relevant scale up examples

Org. Process Res. Dev. 2015, 19,1580−1589

5 g scale

Green Review

-

Atom efficiency (by-products, molecular weight)

Catalytic technology—but enzyme loading should be optimized and steps using stoichiometric reagents like cofactor recycle should be optimized to avoid unnecessary excess of reagents. - Safety Concerns

Generally considered a safe technology to scale-up. Issues—enzymes/proteins can be sensitizers by inhalation, and some by mode of action can be skin irritants (proteases). If viable GMO cells are used, local regulations relating to use of GMOs need to be followed. - Toxicity and environmental/aquatic impact

No real concerns—enzymes are non-toxic and readily biodegradable. If viable GMO cells are used, these need to be passivated before discharge into the environment. - Cost, availability & sustainable feedstocks

Enzymes are produced from natural sustainable feedstocks. - Sustainable implications

Enzymes are made via fermentation; cloned and recombinant enzymes would be at no risk from depletion. Enzymes break down in the environment and the constituent amino acids are recycled in nature. The use of over expressed recombinant enzymes is generally much better than natural enzymes on a life cycle impact basis.