Bayer-Villiger Monooxygenase (BVMO)

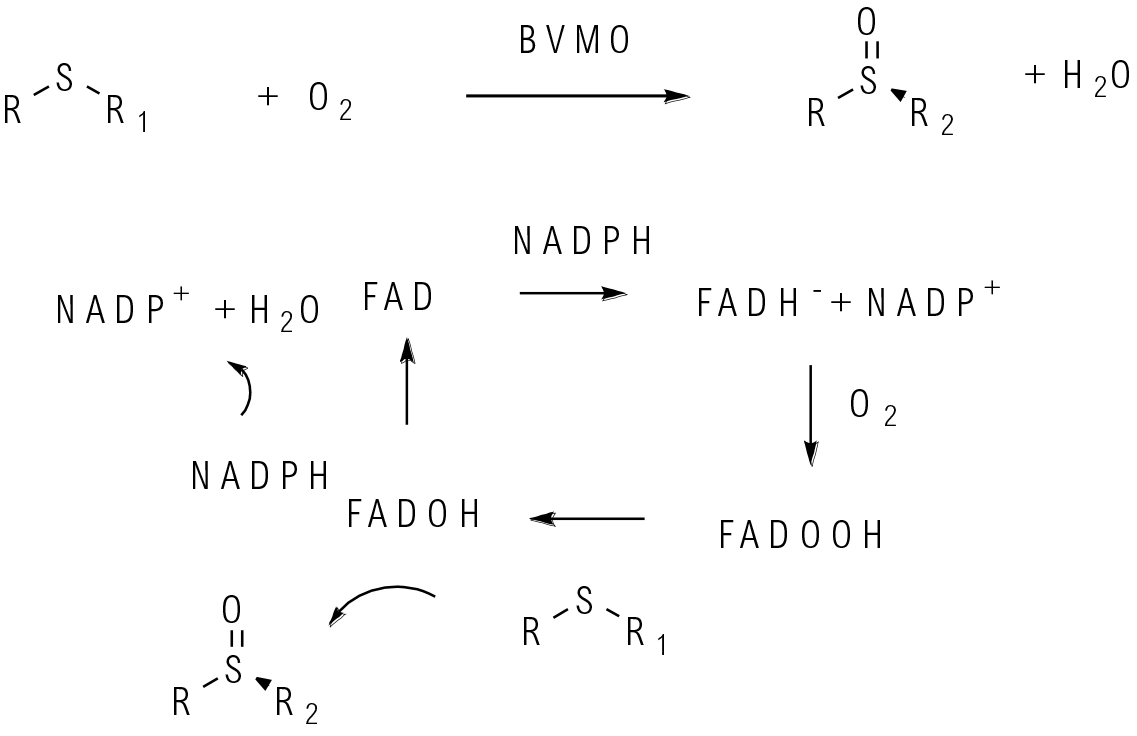

Mechanism + Description

Baeyer-Villiger monooxygenase (BVMO) enzymes utilise a flavin cofactor which is oxidised to a flavin hydroperoxide by atmospheric oxygen. This oxidises the substrate and the catalytic cycle is completed by reduction of the flavin oxide with NAD(P)H.

General comments

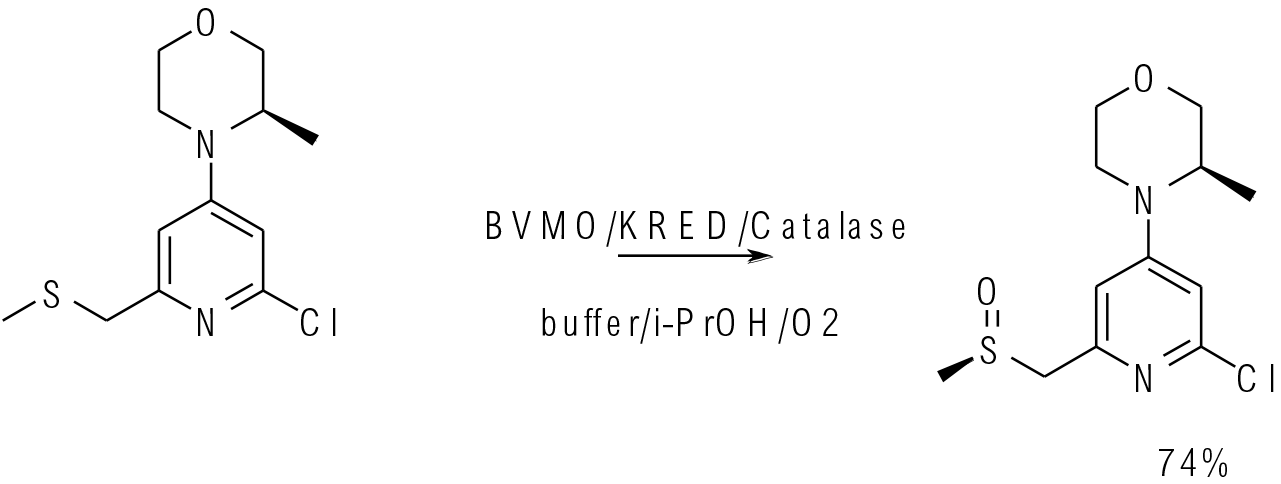

BVMO enzymes act fundamentally as chiral peracids, the reactive intermediate flavin hydroperoxide being bound in the chiral active site of the enzyme and delivering the oxygen from one prochiral face of the substrate to be oxidised. The reaction needs air/O2 and since the catalytic cycle is completed by NAD(P)H regeneration of the reduced flavin, a NAD(P)H regeneration system also needs to be in place. BVMO enzymes are essentially used for two synthetic reactions, 1) the classical Baeyer-Villiger reaction converting ketones to esters, and 2) the oxidation of heteroatoms to oxides—notably the conversion of sulphides to single enantiomer sulphoxides with little or no over-oxidation to the sulfone.

Key references

Rodríguez-Mata, M.; Lavandera, I.; Gotor-Fernández, V.; Gotor, V.; García-Cerrada, S.; Mendiola, J.; de Frutos, Ó.; Collado, I. Baeyer Villiger monooxygenase-catalyzed desymmetrizations of cyclobutanones. Application to the synthesis of valuable spirolactones.

Tetrahedron 2016, 77, 7268–7275.

Relevant scale up examples

J. Org. Chem. 2018, 83, 7453−7458

1 kg scale

Org. Process Res. Dev. 2017, 21, 107–113

80 kg scale

Org. Process Res. Dev. 2008, 12, 660–665

1 kg scale

Green Review

-

Atom efficiency (by-products, molecular weight)

Catalytic technology—but enzyme loading should be optimized and steps using stoichiometric reagents like cofactor recycle should be optimized to avoid unnecessary excess of reagents. - Safety Concerns

Generally considered a safe technology to scale-up. Issues—enzymes/proteins can be sensitizers by inhalation, and some by mode of action can be skin irritants (proteases). If viable GMO cells are used, local regulations relating to use of GMOs need to be followed. - Toxicity and environmental/aquatic impact

No real concerns—enzymes are non-toxic and readily biodegradable. If viable GMO cells are used, these need to be passivated before discharge into the environment. - Cost, availability & sustainable feedstocks

Enzymes are produced from natural sustainable feedstocks. - Sustainable implications

Enzymes are made via fermentation; cloned and recombinant enzymes would be at no risk from depletion. Enzymes break down in the environment and the constituent amino acids are recycled in nature. The use of over expressed recombinant enzymes is generally much better than natural enzymes on a life cycle impact basis.